PUR Hot Melt Glue Lamination Machine with 1300mm PVC Film for Wall Partition

Basic Info.

| Model NO. | CLF-PT1300 |

| Performance | Anticorrosive |

| Speed | 3-25m/Min |

| Lamination Width | 15-1220mm |

| Power | 25kw |

| Winding Diameter | 600mm(Max) |

| Glue Type | PUR Hot Melt Glue |

| Warranty of Core Components | 1year |

| Lamination Height | 1-50mm |

| Video Outgoing-Inspection | Provided |

| Applicable Industries | Woodworking Machinery Industry, Furniture Industr |

| Key Selling Points | Quick Replacement System |

| Weight (Kg) | 8000 |

| Condition | New |

| Core Components | PLC, Engine |

| Transport Package | Stretch Film and and Plastic Film |

| Specification | 15960*2620*3200mm |

| Trademark | COLOURFUL |

| Origin | Qingdao, China |

| HS Code | 8477599000 |

| Production Capacity | 30 Set/Sets Per Month |

Product Description

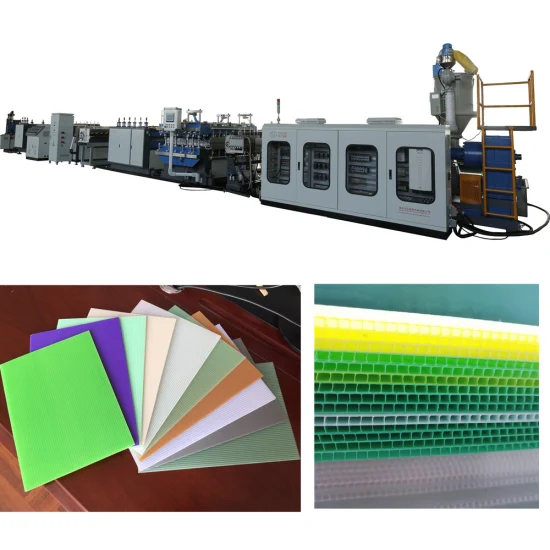

PUR hot melt glue lamination machine with 1300mm PVC film for wall partition

Product Description

This machine is a roller coating equipment, which applies glue to the surface of the board; this machine can be used on MDF board, particleboard, particleboard, calcium silicate board, glass magnesium board, PVC foam board, aluminum board, wood plastic door, and other boards Surface laminated with PVC film, wrapping paper, veneer, CPL, leather, aluminum foil, copper foil, and other roll fabrics can also be laminated with acrylic sheet, single veneer, PET sheet, fireproof sheet, and other single sheet materials

Detailed Photos

Product Parameters

| Overall Size | 14500x2970x2500mm |

| Weight | Approx. 8000 kg |

| Power Supply | 380V 50Hz or customized |

| Total Power | 25 kW |

| Air source | 0.3- 0.5 MPa |

| Working Speed | 3-25m/min |

| Glue amount | 25-35g |

| winding diameter | 600mm(max) |

| Lamination width | 1220mm |

| Lamination height | 1-50mm |

| Film application Spec | film Width 1300mm |

| Glue Melter | Barrel TypePail: 55gallonNum. of Hoses: 1Temp. Control Sensor: PT100Glue Type: PUR. |

| Control System | Schneide-r PLC with 10in. full-color touch screen. |

| Electronic Components | Schneide-r |

| Pneumatic Components | AirTac or equivalent |

| Optional | Can be customized |

Certifications

Packaging & Shipping

After Sales Service

Company Profile

Qingdao colourful machinery Co., Ltd is a company integrating design and research, production, domestic and international sales, China Construction Metal Structure Association, China Construction Metal Structure Association, Board of Directors of Qingdao Furniture Association, we focus on the design and research of various decoration materials surface treatment machine. The initial team of the organization is professional engineers who have ten years of experience in this field. The main product include PUR hot glue laminator machine, flat laminator, PUR sheet laminator machine, door panel laminator machine, PUR special-shaped edge banding machine, cold laminator machine, undertake laminating, automatic veneer production line, The machine can work on various profile, board, and sheet, with wood, aluminum alloy, steel, and PVC material, Our various products apply to furniture, door industry, door and windows profile industry, home appliances, automobile, and other industries. Colourful equipment serves many countries and regions in the world, and has won wide praise in the industry.

Profession Seiko chi-made in the customers, Is the value, Is for the customers create ever-increasing value.

Qingdao colourful in order to "Creat value to customers" as the core, Unceasing innovative product and promote quality of service, realize customers′ value of the maximum.

Equipped with professional senior service engineers to provide design solutions and consulting services before the sale, recommend the equipment that best suits the customer′s needs.

Tracking services, free training for customers, guiding installation, carefully explaining the operation points, ensuring efficient operation of products, and minimizing failures caused by improper use of customers.

The service personnel takes the initiative to conduct inspections on a regular basis to test the operation of the equipment and maintain it in time.

In the event of a failure, the professional service personnel can quickly solve the problem and simultaneously summarize the information to establish a classification file for the customer.