Rigid Collapsible Box Making Machine Foldable Storage Box Maker Machine for Cardboard Box Machine

Basic Info.

| Model NO. | ZRL800 |

| Heating Power | 4kw |

| Motor Power | 14.5kw/380V 3phase |

| Machine Weight | 3600kg |

| Machine Dimension (L×w×h) | L8500xw4100xh1900mm |

| Air Supply | 15L/Min 0.6MPa |

| Precision | 0.2mm |

| Production Speed | 22sheets/Min |

| Gluing Line | 0-8PCS |

| Cardboard Thickness | 1~3mm |

| Transport Package | Wooden Case |

| Specification | 4000x1600x1900mm |

| Trademark | Rongda |

| Origin | China |

| HS Code | 84414000 |

| Production Capacity | 100 |

Product Description

ZRL800 Collapsible Box Making Machine

Collapsible box, also called foldable box or book type folding box, which can not only save storage, but also easy to be delivered, is kind of an efficient packaging box. This machine is independently developed by our company and is the first in the world. With the unique glue scraping process and the robot and camera positioning system, it can form a folding box at one time, which overturns the disadvantage of traditional packaging boxes that occupy a large space and perfectly solves the problems of low efficiency and complex process of traditional collapsible boxes.

| Model | Collapsible box type 1 | |

| 1 | Paper Size | Min: 230×230mm, Max: 750×750mm |

| 2 | Creasing Line | Min: 190×190mm, Max: 640×640mm |

| 3 | Paper Thickness | 220~350g/m2 |

| 4 | Cardboard Thickness | 1~3mm |

| 5 | Cardboard Quantity | 4 |

| 6 | Folding Size | 20-120mm |

| 7 | Box Height | 35-120mm |

| Model | Collapsible box type 2 | |

| 1 | Paper Size | MIN: 190×260mm, MAX: 540×750mm |

| 2 | Paper Thickness | 120~250g/m2 |

| 3 | Cardboard Thickness | 1~3mm |

| 4 | Cardboard Quantity | 2 |

| 5 | Box Height | 35-120mm |

| 6 | Gluing Line | 0-8pcs |

| 7 | Paper Stacking Height | 380mm |

| 8 | Precision | ±0.2mm |

| 9 | Case Size | Min: 120×190mm, Max: 450×1000mm |

| 10 | Production Speed | <=22sheets/min |

| 11 | Motor Power | 14.5kw/380v 3phase |

| 12 | Heating Power | 4Kw |

| 13 | Air Supply | 15L/min 0.6MPa |

| 14 | Machine Weight | 3600kg |

| 15 | Machine Dimension | L8500×W4100×H1900mm |

1. Automatically feeding paper

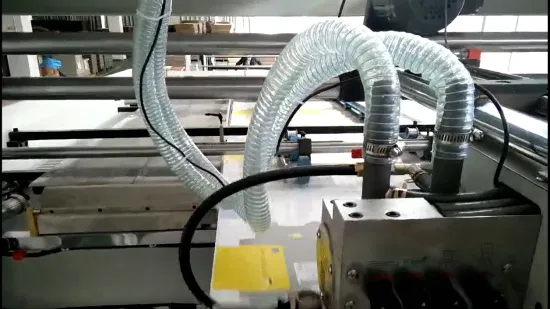

2. Hot melting glue scraping system

3. Automatic four cardboards feeding device.

4. Robot and camera positioning system

5. Automatically folding and pressing.

6. Adopts Germany Beckhoff control system, 21inch touch screen with friendly HMI.

Sample:

Product Packaging

1. What can we do for you?

We have been engaged in rigid box equipment for more than 20 years, and can provide you with a full set of rigid box production solutions.

2.What machines can we offer?

For developing a rigid box production line, the following machines are related.

Die cutting machine, V grooving machine, Magnet pasting machine, Ribbon pasting machine, Case making machine, Rigid box making machine, Gluing machine, Box wrapping machine, Assembling machine, Bubble pressing machine, Packing machine, etc. We will tailor the most suitable plan and equipment for you according to your needs.

3.Warranty?

1 year from the date of installation

4.Installation and training?

Usually, we will send a technician to the customer''s factory to help the customer install the machine and train the workers. The period is 7-15 days (depending on the model). During this period, customers will pay for round-trip air tickets, hotel accommodation, meals, and local transportation.

Due to the pandemic, we currently suspended this service until the end of the epidemic. However, we will help buyer to install the machine online via wechat or whatsapp.

5.What''s the delivery time?

10-30 days after receive the payment.

6.How to confirm the quality of machines?

After the production and debugging of the machine is completed, we provide online demonstration services, so you can fully confirm the equipment.