Solventless Laminating Machine Manufacturers in China Ssen Solventless Laminator 500mpm

Basic Info.

| Model NO. | SEN-1050A, 1350A, 1650A |

| Membrane Material | PET Film |

| Plastic Film Mulching Modes | Two-Layers Lamination Composite |

| Performance | Food Packaging |

| Glue Mixer/Dispenser | Included |

| Tension Control | Automatic by PLC |

| Servo Motor | 7PCS |

| Max.Laminating Speed | 500m/Min |

| Water Heaters | Included |

| Max.Material Width | 1050mm.1350mm,1650mm |

| Transport Package | Iron Bracket+Film Wrapping |

| Specification | 5100*3600*2500mm |

| Trademark | SSEN |

| Origin | China Mainland |

| HS Code | 84778000 |

| Production Capacity | 200sets/Year |

Product Description

Machine basic parameters

| ModelParameter | SEN1050A | SEN1350A | SEN1650A |

| Max.material width | 1050mm | 1350mm | 1650mm |

| Max.unwind diameter | φ800mm | φ800mm | φ800mm |

| Max.rewind diameter | φ800mm | φ800mm | φ800mm |

| Total power | 53kw | 58kw | 62kw |

| Water heater included | 3sets | 3sets | 3sets |

| 2-component glue mixer | 1set | 1set | 1set |

| G.Weight | 11000kgs | 13000kgs | 15000kgs |

| Dimension(L*W*H) | 5800*3000*3050mm | 5800*3300*3050mm | 5800*3600*3050mm |

Substrate Types

| Laminating substrates | Thickness of substrates | Coating substrates | Thickness of substrates | |

| BOPP | 12-80μm | BOPP | 12-80μm | |

| PETP | 8-30μm | PETP | 10-30μm | |

| LDPE,LLDPE | 20-200μm | LDPE,LLDPE | 30-200μm | |

| OPA | 12-18μm | OPA | 12-18μm | |

| NYLON CAST | 20-80μm | NYLON CAST | 30-80μm | |

| ALU(Foil) | 6.3-40μm | PP CAST | 60-150μm | |

| PP CAST | 20-150μm | PAPER | 40-150gsm | |

| COEX FILM | 20-200μm | |||

| PAPER | 40-150gsm |

Packaging & Shipping

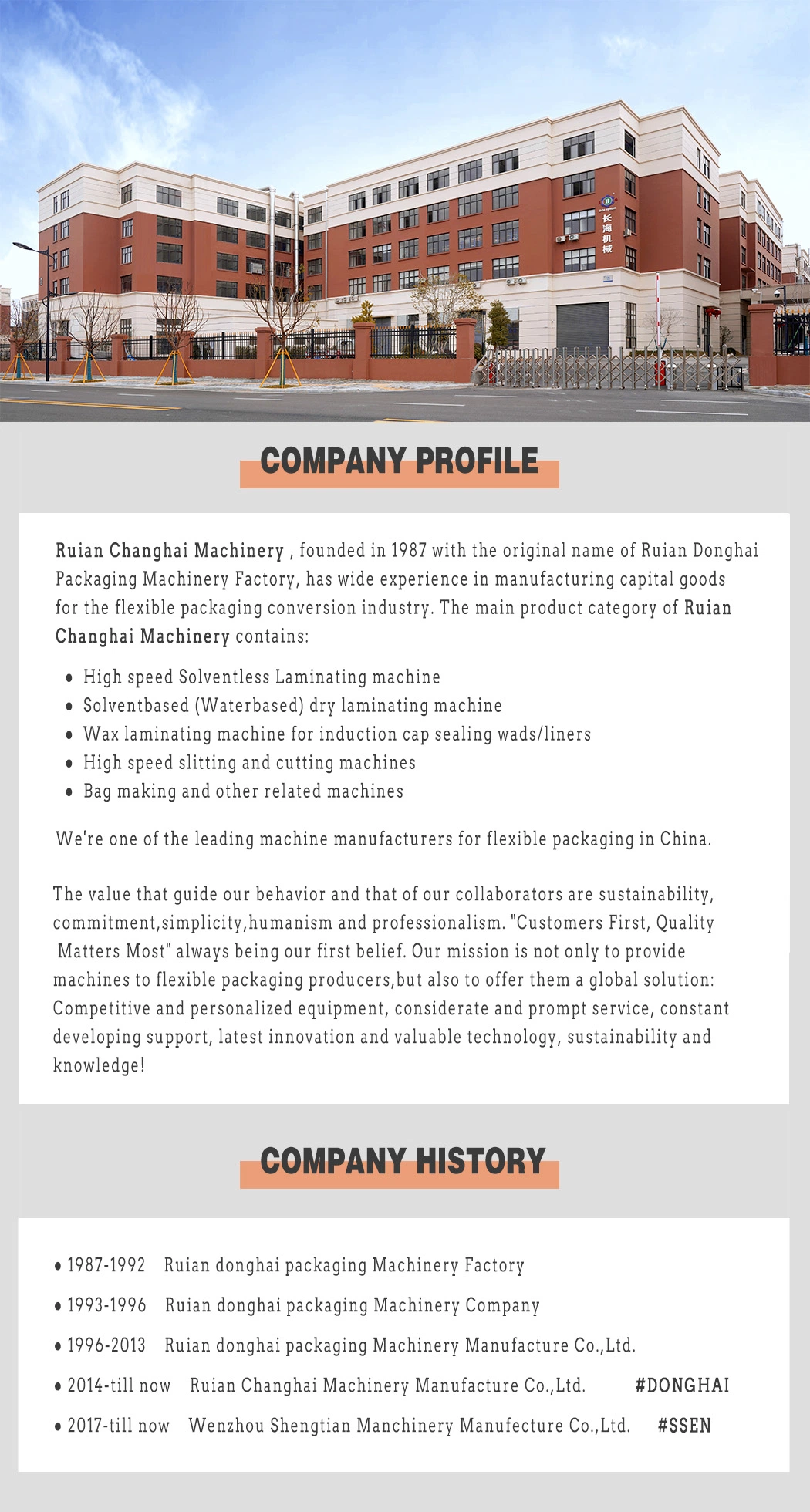

Company Profile

After Sales Service

As the ultimate manufacturing factory, we not only provide you competitive factory price, visible capital goods,but also more invisible values including:

1) In-time delivery

2) One year quality guarantee and overseas technical service

3) Competitive factory price without any third party involved

4) Tailored solutions for specific demand and requirements provided

5) Quick delivery for spare parts

6) Fast response to customer's confusions

7) Keep customers updated with the production steps

8) Strict quality control during production and do inspection before delivery

9) Instant remote technical consultation and operation guidance

10) Shipping following up until goods arrives at destination safely